New features of Perfect Cut Release 6.4 Service Pack 3

Linked Pieces

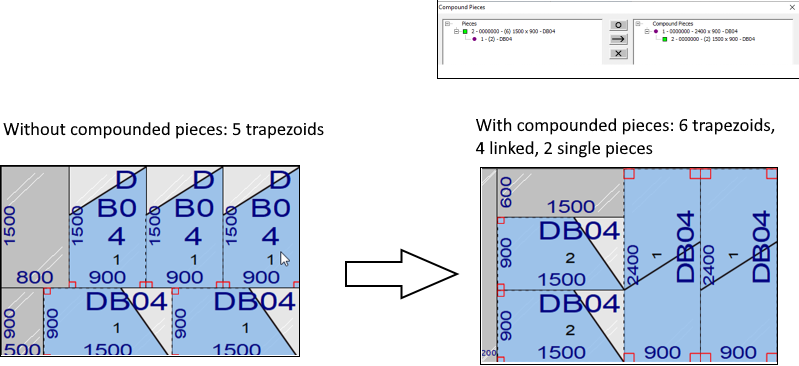

A new interface allows to define some “compounded” pieces, a special type of pieces which include multiple pieces inside itself (for example, a couple of triangles or a couple of trapezoids) to allow filling the rectangular piece better and thus reduce the amount of scrap.

The interface is accessible through the “tools” menu or the = button on the pieces window.

It’s also possible to import directly the linked pieces through .IMP files, filling the subfield 13 of Note2 of the linked piece “PieceID-amount^PieceID2-amount2^…”.

In the following example, the piece 1 includes two rectangular trapezoids with code 2 to reduce the scrap.

Optimization for pieces with high quantities

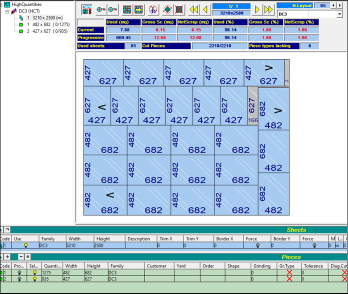

A new particular optimization, “Optimization for pieces with high quantities”, has been implemented, which can create better results when the projects have very high quantities in the single rows of the pieces. The optimization with the best results between this new one and the old one gets chosen by PerfectCut.

Cutting layouts

On the layouts shown in Perfect Cut, TV and NC it’s now possible to select one or more tails and add them directly to the stock, through the right click menu.

On the layouts shown in Perfect Cut, TV and NC it’s now possible to select one or more tails and add them directly to the stock, through the right click menu.

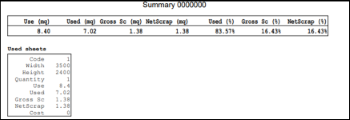

The information relative to net/gross scrap and used area for each type of sheet has been added to the summary print.

OPT file import from batch file

The possibility to import an external file (OPT, OTD) from the batch file has been implemented by inserting a row with the key “IMPEXT”, for example “IMPEXT <file_full_name>.OPT”, which includes the possibility to use the /NC parameter to define that the file will have to be copied on a path defined in the Perfect Cut configuration and that a new management with traffic light-style files (ACK1, ACK2 and ACK3) to represent the different phases the file is going through (handled by Perfect Cut, handled by Perfect NC, start of cutting from the machine operator, end of cutting), to handle future dynamic optimization solutions.

Shape management

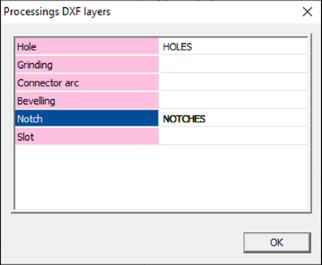

A new interface allows to define for each Shape Plus processing type an alphanumeric name of the layer included in the DXF file, opened through configuration -> CAD -> “Processings DXF layers”.

The segments of a shape with tangential difference of 0 will now be united as a single cutting line, if they use the same cutting tool. This new feature includes the LowE wheel handling on the breaking lines, if such management is enabled on the family.

Rack Management

It’s now possible to rotate an entire pile directly from the pile list of the rack.

If a rack type has been binded to a piece and the piece doesn’t fit in the racks defined, other rack types will now be considered as valid if they are enabled to the destination of the piece, in order to avoid not having the piece assigned to the delivery racks.

New configuration options

It’s now possible to set a reduced version of the management of automatic stocks, which excludes the creation of lists for the sheet loader and only enables the reading of the stock quantities and statuses.

Through the file CONFIG_LIST.INI in the installation directory, the possibility of defining a backup path of the database projects (if the DB Browser function is activated In the Perfect Cut) has been introduced: [PATH_BACKUP] PATH_BACKUP=chosen path.

Intermac NC

It’s now possible to enable “only true entities” on a LowE material to allow the use of the LowE wheel only on rectangular pieces and on the shape entities, excluding the rectangles that contain shapes without entities on the borders like circles. This new function alternatively to “LowE on break lines”.

For each material it’s also possible to set a different value for the width of the LowE elimination, which overrides the one defined in configuration.

Monolithic NC, LowE management: the handling of the advancing of LowE elimination on shapes has been fixed, also considering the advancing of elimination defined on the border of the sheets when the shapes are positioned on said borders.

For the laminated NCs combined with a monolithic NC for the printing of labels or LowE removal, the transformation of the laminated layouts now happen before the creation of ISO files for the monolithic NC to avoid differences between the schemes for the two NCs.

Macotec NC

Nested cuts: a limit for the maximum size of the leftover after the last nested cut has been introduced, over which the relative sub-transversal sheet will not be handled using nested cuts. Moreover, it’s now preferred to not increase the cutting level over Z even if “Path optimization” or “Consider number of cuts and rotations”.

For the LowE management it’s now possible to define different parameters for the first, second and third passes of the roller. If there are additional ones, the value for the third pass will be used instead.

For the laminated NCs the possibility of defining the lower limits of width and height of a leftover from a cut has been added, and if the leftover is under both these limits the cut will only be scored but not detached.