New features of Perfect Cut Release 6.4 Service Pack 6

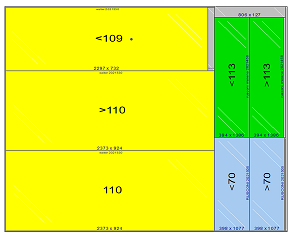

Customizable colours for layout pieces

It’s now possible to select which color to display the pieces in the cutting layouts to help operators to differentiate different group of pieces. The colors are defined as $COLOR (ex. $YELLOW) in the yard field and it’s possible to customize the RGB definition in the COLORS.INI file in the installation folder.

Example of row in COLORS.INI: YELLOW=255,255,0

This coloring is displayed in all the Suite programs (Cut, TV, etc) and in the cutting layout prints.

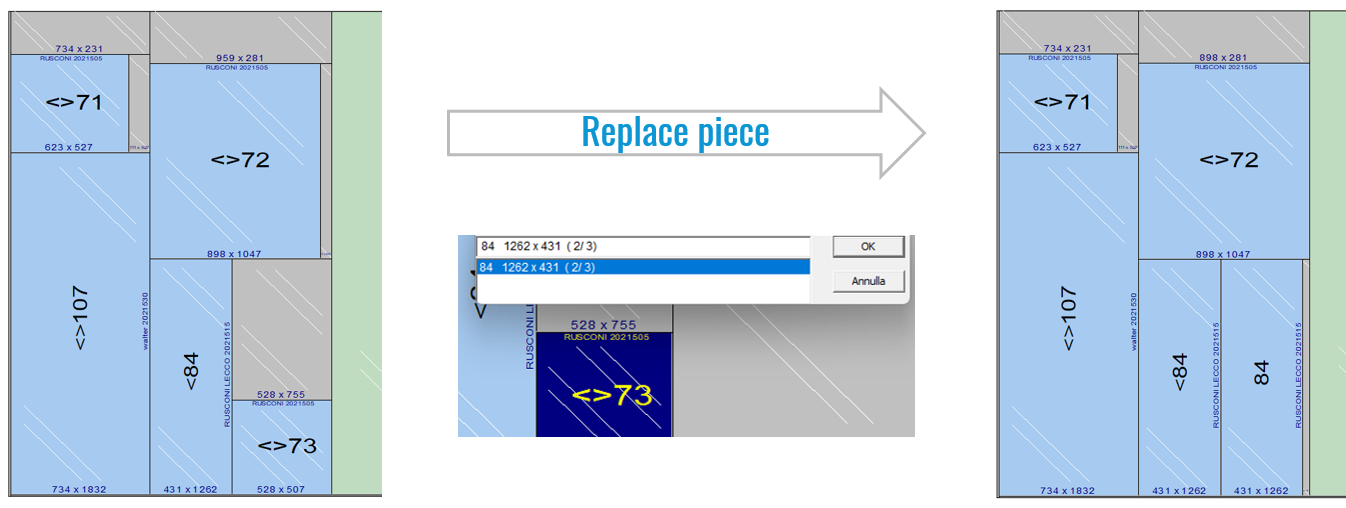

New Functionalities – Graphic editor

The possibility to replace a piece in the cutting layouts, either with another pre-existing piece (with enough residual quantity) or a new one with customizable sizes has been added to the editor of Perfect Cut.

New Functionalities – Perfect Cut

In a project containing more than one family, it’s now possible to split it in multiple projects for each family using the «Split for each layout» function, available in the menu on the project name.

Example.OT5 (F4/10/F10)

split for each family:

- Example_F4.OT5

- Example_F10.OT5

A CRC check has been added when loading the configuration file, and if an error is detected the program will restore the last backup copy of the configuration, which is automatically stored when the configuration is loaded correctly.

New Functionalities – Projects on SQL

It’s now possible to enable the automatic export of information of the projects on the SQL database while saving the projects, useful for example to upload information for estimates that don’t require the generation of files for the NC.

The physical space occupied by .OT5 files on the SQL has been extremely reduced, with results of over 90% reduced space compared to older versions.

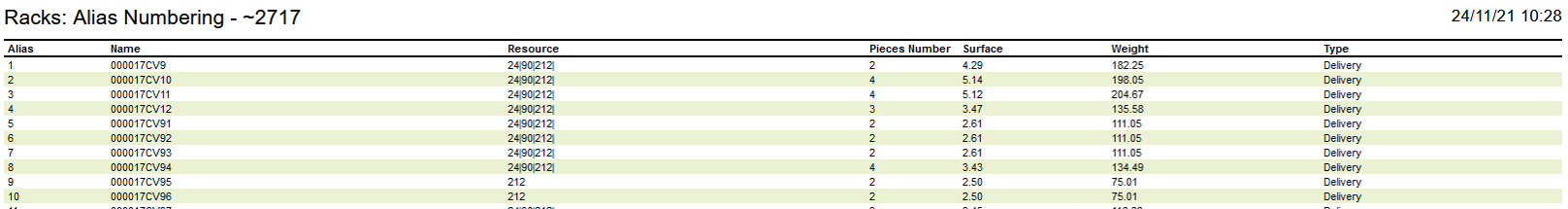

Rack Management

It’s now possible to represent the codes of the racks with a progressive alias code inside a project by enabling the «Alias numbering» field in the configuration.

If this new functionality is enabled, it’s also possible to print a new report that displays the correlation between the internal incremental alias and the «real» rack code, with an additional information of the pieces contained (number of pieces, weight, type of racks and destination resources).

Screenshot

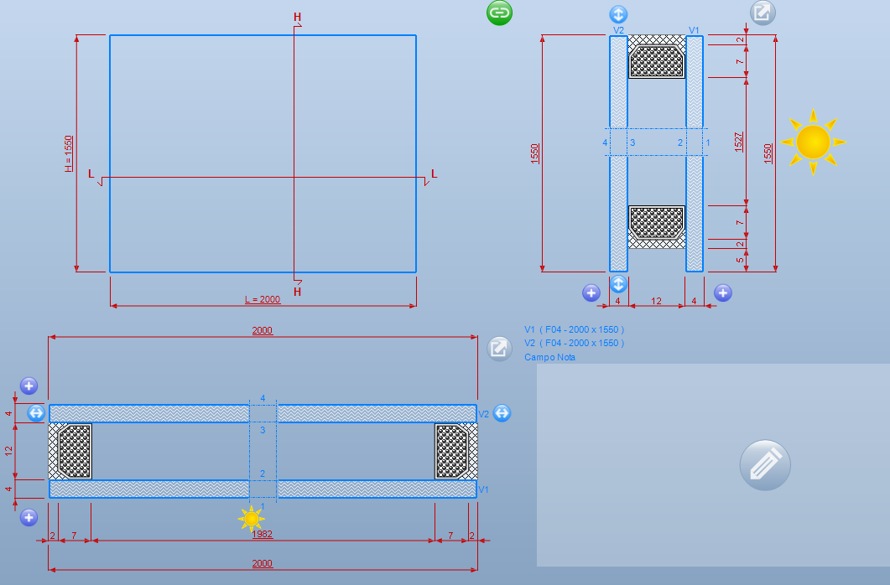

Rack Management

The «Delta Height» parameter has been added to the rack type editor for the height difference for the A/L type racks, instead of being only valid for the second side of a rack. If this parameter is set to 0 it will take the default parameter «Delta max height standard» in the configuration instead.

The rack print report now also shows the assembling sequence, if available.

It’s also now possible to define the family sorting for all classification types, instead of being exclusive to tempered glasses, if the installation is working with «machine» harp rack types.

New Functionalities – Perfect Label

External software can now temporarily force the “For each glass” flag to print the labels.

In order to align with Perfect Cut, the fields “Spacer reduction”, “Elimination” and “Rack parameters” were added to the Label interface as well.

For all sorting types, it’s now possible to print the information relative to both assigned racks (cutting and delivery), if available in the optimization.

Standardization of spacer reduction

The management of the spacer reduction values has been standardized across all use cases, including the default value in configuration, the particular value set on a single piece or if it’s set through the step unit interface.

Improvements – Lisec Import

The «Low emission correction» parameter has been added, which gets added to the relative value read from the Lisec file and can change between different installation of Lisec software.

In the case of import using the rack management, «parked» pieces will now be displayed with a ! at the end of the rack indication to warn that the piece is outside the normal rack sequence.

NC Intermac

The management of the different configurations for the machines has been improved and it’s not possible to set multiple machines with the same type (ex. Genius CT / LM37). The association is now done using both the model type and the machine name set in the configuration, so it’s possible to avoid using the «Genius CT2» type that was added to manage installations with two CT machines.

New Numerical Controls

Perfect Cut is now compatible with BILGE numerical controls, including the special laminated cutting machine mirrored on the Y axis.

Perfect Cut is also now compatible with VETROMAC numerical controls.

New shaped cut processing for Macotec STR

A new management for shaped cutting on laminated Macotec NC has been developed.

Using a new special processing of shaped pieces into dedicated transversal in a layout, the algorithm tries to bundle together all the shaped pieces in the same transversals and reduce the workload of the machine as much as possible. These transversals will only be scored and not opened as a single unified shape that is made of all the internal cuts.

New shaped cut processing for Macotec STR

To customize this new functionality, multiple new parameters and weights have been added in the «Shapes processing for transversals» section of the laminated cut configuration.

This new processing is fully compatible with all the other special processings available like «Grinding for transversals» and «Squaring in combined mode».

It’s also possible to set different types of processing of the special shaped transversals and choose if and when to open the cutting lines.

Perfect TV – Macotec STR

The new shaped transversal processing has been fully integrated in Perfect TV, showing the linear cuts of the special transversal in red when they’re getting scored, and the transversal will be highlighted when the shaped cut is being executed.

In the information window of the active cutting layout, the index of the machine step and the total amount of machine steps are now shown instead of the cut step, to include all the steps without cutting (including for example the new special transversal processing).

It’s now also possible to delegate which pieces are shown on the out-feed window to the MacoLayer interface by enabling the «Delivering from MacoLayer» check in the configuration.