New features of Perfect Cut Release 6.4

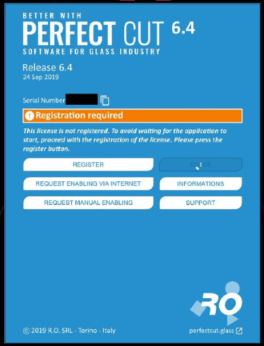

New license registration

The registration of licenses is now done through a new online procedure.

When an installation of Perfect Cut is opened without a registered license, it will now ask to register it: a webpage on perfectcut.glass will be opened which requires to insert some information about who is registering, especially an e-mail address which will receive an email to confirm the registration.

In case the computer with Perfect Cut is not connected to the internet, it’s possible to register the license through another computer with a working internet connection.

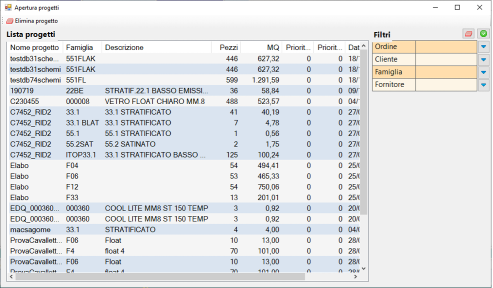

SQL database for optimization projects

It’s now possible to save and read projects on a database. This functionality is parallel to the .OT5 files, but allows more computers to read from a single database different projects.

The new database interface is accessible through the File menu -> Open from database.

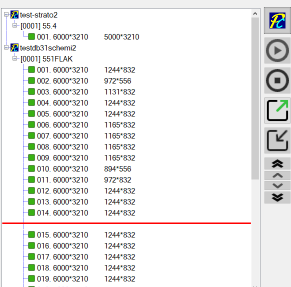

Perfect List: managing projects on the machine

Using our new module Perfect List it is now possible, for Macotec machines using NC or TV, to queue multiple projects to be cut on the machine.

The projects are loaded from two databases (one from the office and one local) managed by Perfect Cut and the interface of Perfect List allows to reorder schemes, decide to skip some of them or stop the automatic execution whenever wanted.

Opening one of the «active» projects on Perfect Cut will show which schemes are already completed and which ones can still be modified before being cut on the machine.

Racks stock on SQL database

A new feature allows to manage a stock of the cut pieces on harp racks using an SQL Server database.

When the pieces in a project are assigned to a harp rack, they’ll now also be uploaded onto the database.

This allows external programs to interact with the content of the racks, and any change to the rack will be reflected on Perfect Cut as well.

From the stock of Perfect Cut it’s also possible to view the current status of the racks and modify them – removing or moving pieces.

Rack management

- It’s now possible to define an alias for a rack type, allowing to use less characters in prints.

- Freeing a rack in the stock is now easily accessible through right-clicking the rack in the stock.

- A new flag «Sort mode with assembly sequence» allows to bind the assembling order to the sequence of the creation of the racks for delivery in order to avoid jumping between different jobs.

Perfect Editor

On projects and families it’s now possible to set the automatic separation of repetitions.

Using the editor of the cutting layouts it’s also possible to separate the repetitions by using a new option in the right-click menu.

On this same menu a new function that allows to add a descriptive note to the layout.

The possibility to define a priority for each project and family has been implemented in order to help choosing which project to cut first. The priority is shown between square brackets on the field it has been set to (family or project).

Completed repetitions management

For the numerical controls Macotec and GFP it’s possible to manage modifications to a layout with repetitions already completed. Setting the flag «divide executed repetitions» in the General configuration, the completed repetition will be blocked in the Perfect Cut editor. In case a layout has been only partially completed (with some repetitions still to be cut), it’s possible to duplicate the layout in order to modify only the repetitions yet to be cut.

Example:

Partially completed layout ( 2 / 5 )

CHANGES TO THE LAYOUT

Original layout ( 2 / 2) + Modified layout ( 0 / 3 )

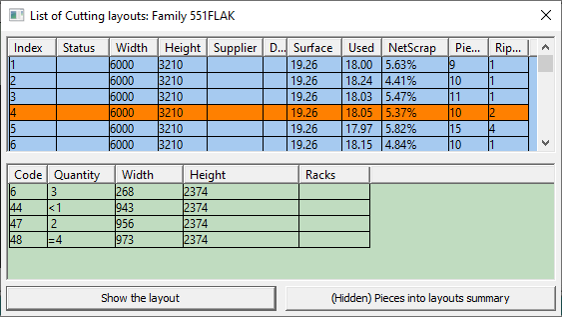

Layouts report for families

For each family in a project a new report of the layouts has been introduced, accessible through right-clicking the family that you want to analyze.

This report shows the list of the layouts optimized for the family, with all the information about status (completed, being worked on, ready to be cut), the sheet used, supplier, amount of pieces and areas.

It’s also possible to see the details of the pieces in every layout using «pieces layout summary».

Perfect Label

In the Perfect Label editor it’s now possible to rotate fields by 90 degrees using the right-click menu on the fields.

For the barcode fields it’s also possible to hide the text usually shown under the barcode.

On Perfect TV and Perfect NC it’s possible to print the labels of the pieces in a cutting layout using the right click menu on the layout interested.

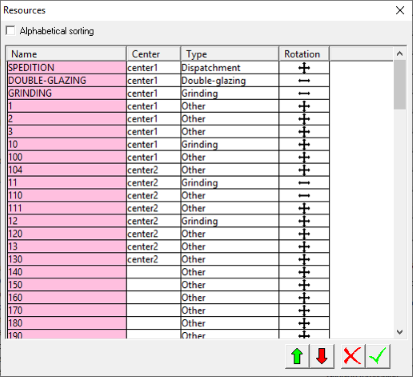

New interface for resources

The user interface used to configure the resources/departments on Perfect Cut has been redesigned.

Defining the center of the resources is easier and a new column «Rotation» has been added, which allows to define a forced placement for the pieces (vertical or horizontal).

It’s also possible to order the list alphabetically for an easier display of the full list.

Perfect Cut

- In addition to the already available filter for supplier, it’s also possible to search in the stock of the families by code, description, numerical control and machine associated.

- The flag «Store discharge when sent to NC» now reduces the quantities of standard pieces project automatically.

- Clicking on the column WIDTH or HEIGHT, it’s possible to sort the pieces by dimension, decrementally or incrementally, considering the minimum dimension or the maximum one.

Perfect Shape

- The import from DXF now supports the instructions BLOCK of the DXF format.

- Perfect Shape allows now to insert a value for the gap on the piece borders for the break lines.

- Inside the IPF it’s also possible to use some variables reffering to the values inserted in the modifications applied to the shapes (offset, border, trim, scaling, mirror).

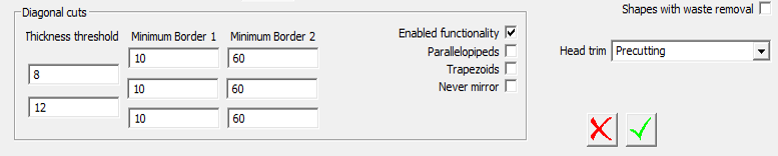

Intermac Laminated NC: Diagonal Cuts

- The diagonal cuts can now handle trapezoids and multiple parallelopipeds, either by difference or not.

In the configuration of the laminated cut of the NC Intermac the flags «Enabled functionality», «parallelopipeds» and/or «trapezoids» need to be checked. For both cases the waste removal functionality can be enabled by enabling the flag with the same name. - For the diagonal cuts it’s possible to define «Never mirror», even for non-LowE material.

- It’s also possible to define 3 couples of values for minimum border 1 and 2, representing the minimum distances from the extremes of the diagonals to the angles of the closest side, to be applied depending on two different thresholds.

Intermac Laminated NC: LowE

- On combined machines, it’s possible to define the flag «RemoveLowE_cmb» to enable the management of the LowE on the monolithic machine.

- In the dialog of the families it’s possible to define a particular type of LowE (i.e. ISIPRO), to define if the break lines have to be included in the LowE steps.

In addition it’s possible to define the number of LowE steps and how many millimiters of LowE overlapping over the cutting line. - The LowE steps on the borders of the sheet are added at the end of all the normal LowE steps and with a fixed direction to reduce the wear of the wheel.

Intermac Laminated NC: Labeling

- On combined machines, it’s possible to define the flag ««ApplyLabel_cmb» to enable the management of the labeling on the monolithic machine.

- It’s now possible to define the rotation, +90 (clockwise) or -90 (counterclockwise) of the labels. When it’s set to 90 degrees, the position of the label is always considered on the longest side of the piece.