New features of Perfect Cut Release 6.3 Service Pack 3

Printing labels of cutting layouts

It is now possible to print the labels of a cutting layout directly from its view.

Independent field prefix

In the editor of Perfect Label it is now possible to set a custom prefix for each field.

New rotation binding

A new type of fixed rotation which forces the “width” of a piece on the vertical axis of the sheet has been added.

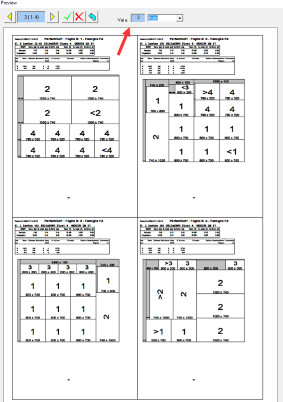

Print preview

The print preview window was updated to show the multiple print for the cutting layouts.

It is now possible to jump to the desired page via the “Go to:” field.

Display configurations

The “Display” configurations of the pieces informations have been expanded and improved.

Moreover, the color of shapes has been changed to allow a better distinction with the normal pieces

Guiding crosses

A new type of “Diagonal Cuts” is now available, which allows to draw a cross giving its center position and its radius.

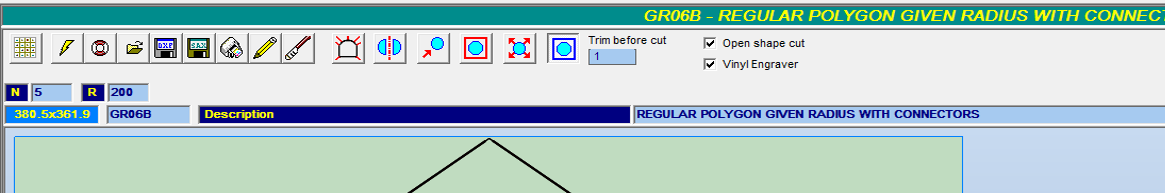

Default shaped cut mode

In the “CAD” section of the configuration it is possible to set the default value of the shaped cut mode in the Perfect Shape interface, choosing between the standard or the open one.

Vinyl tool

In the Perfect Shape interface it is now possible to set the use of the vinyl engraver on every shape.

It is also possible to set this parameter in the import file.

N1=GR06B.dxf[VINYL=1];N=1;B=;H=;;;FAM=F4

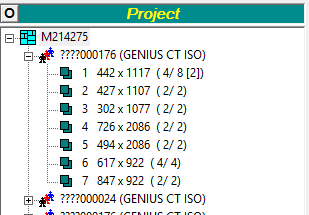

Import families not in stock

Now whenever you try to import a file in PerfectCut, it is allowed to import families that are not present in the stock.

The names of these missing families are shown as “????<family_name>” to indicate that you’ll need to insert the parameters of these families in the stock.

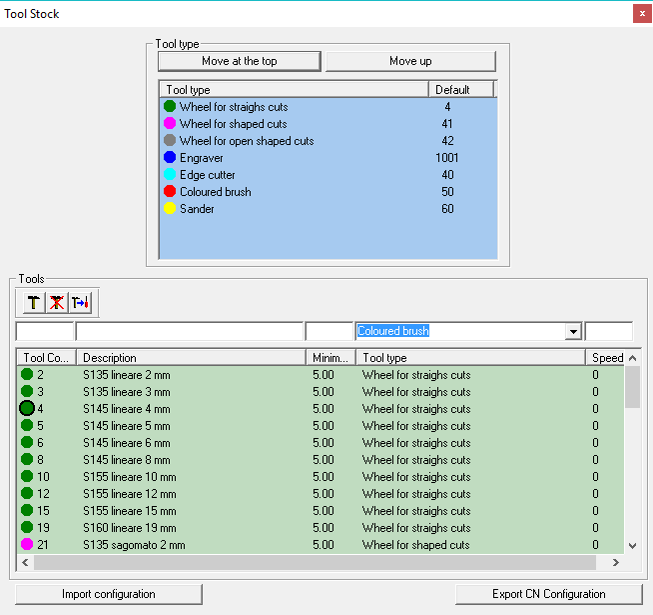

Import / Export machine tools

The import/export functionalities of the tool configurations of Intermac machines have been added. The default tools of the assigned families to the Intermac numerical control are also managed

Intermac NC constraints

The laminated cutting management has been improved to consider to order of importance of the constraints, which are now strictly considered in the following order: maximum cut size, minimum width of the first transversal, maximum buffer usage and the minimum of the last transversal on every cutting level.

Updates for numerical controls

CMS Festo: management of the cut off of X / Y trims according to the maximum quote used on the sheet.

NC Macotec: it is now possible to split a sheet in cuts that contain shapes

NC GFP monolitic: it is now possible to manually set the cutting type without having to pause the NC.