New features of Perfect Cut Release 6.3 Service Pack 4

Sorting of import fields

It is now possible to define different sequences for the fields of the import files (Import Excel and ASCII file).

New import functionalities

As it already happens in Perfect Cut, now Perfect Label too allows to import files with families which are not defined in the stock. When families are not imported into Perfect Cut, it is now possible to specify the name of the machine to which it is assigned, not just the numerical code of said machine.

Shapes

In the parametric .IPF files it is now possible to specify the offset using the #OFFSET method. If the offset wanted is an inner one, the value will have to be negative.

#OFFSET[valore offset, variabile1, variabile2, … variabileN]

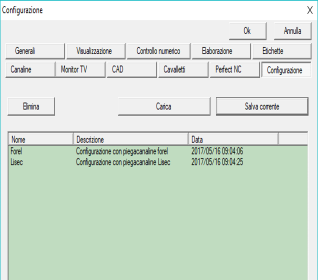

Backup and restoring of configurations

A new page in the configuration dialog allows you to save and restore different configurations.

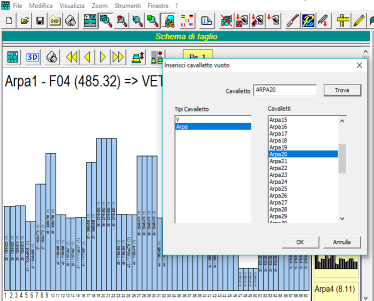

Rack selection in the editor

When you try to add or modify a rack in the Perfect Rack editor, a window appears and shows the rack types and for each type the available racks.

Demo with remote R.O. key

It is now possible to use a DEMO key on the R.O. server remotely, properly enabled to the request features.

It is now not necessary to send a key to the client, but it requires an Internet connection to access it.

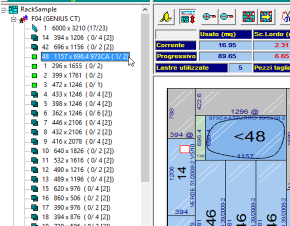

User Interface Improvements

When a cutting layout is edited, the tree view keeps showing your last selected item. Furthermore, the color of the shapes has been changed to allow a better distinction with the rectangular pieces.

Interaction with Movetro database

The possibility to read values in fractional inches directly from the Movetro database has been introduced.

The sizes in the lists for the loader are approximated using the same method used by Movetro, allowing them to find the correct sheet.

In the configuration it is possible to set which version of the Movetro stock you want to use: 0 will read values in millimeter, 1 will also read the variables to manage the fractional inches.

LowE

In rectangular pieces, the direction of the inner steps is now determinated according to which cutting line it is parallel to.

For the inner steps of the shapes with an elimination defined on the entities, the direction of the inner steps is now concordant to the direction of the cutting lines.

For the laminated material, the possibility to manage the squaring on the monolith table has been added, in addition to the already possible combined settings (linear cuts, shapes, diagonal cuts).

LowE

Intermac NC: In addition to the combined settings already configurable (linear cuts, shapes, diagonal cuts), it is now possible to set the squaring on the monolitic cutting table for laminated LowE glasses.

Macotec NC: management of the squaring on the monolitic cutting table in case of laminated LowE glasses.

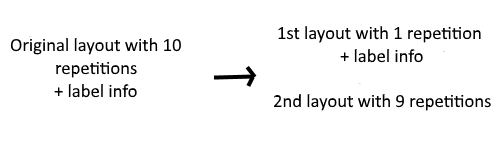

Perfect Label synchronism

If in the label configuration the “one each type” option is selected, each cutting layout with N repetitions will be split in two different layouts: the first, with only one repetition, will have all the label information, while the second one will have the remaining repetitions without the label information.

If “one each package” is selected instead, the layout will be split in N different ones: the first one with one repetition will contain all labels informations, while the second one will have the remaining repetition without any labels informations.