Low-e glasses management with TPF

The low-e glass with TPF (Temporary Protective Film) is a particular glass with an additional protective coating in the form of plastic film. In order to properly cut this kind of glass it has been necessary to develop a technology capable of removing such film prior to coating removal.

How Perfect Cut deals with TPF

Perfect Cut can handle this particular situation ensuring high speed, an excellent grinding quality and the extreme sheet cleanliness without producing any plastic residue.

In reference to the TPF removal and low-e gringing, Perfect Cut allows to:

- Follow straight, geometric shapes and also curvilinear paths

- Follow paths with more than the usual 10 mm width in order to achieve grindings bigger than the tool width, in “multi-step”

- Obtain through a particular grinding management, an high quality and homogeneity of the grinded edges

If the head ends at a point which no previous 90° perpendicular removal has occurred, special measures must be taken to avoid that lifting the head, the film stick to the grinder.

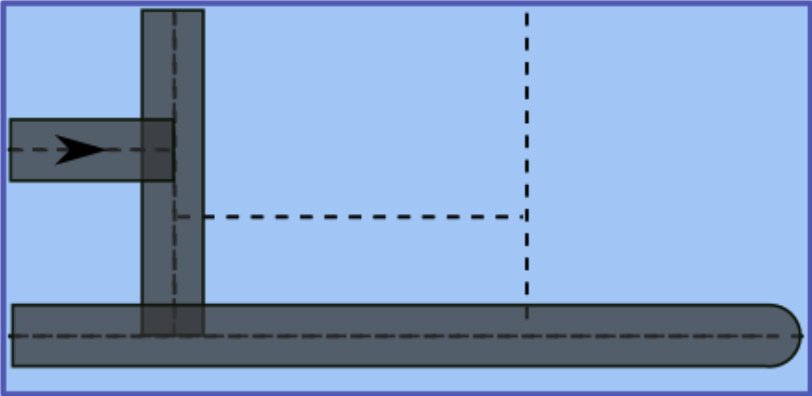

In case of multi-step (when the removal width is greater than the tool diameter, tipically more than 20 mm) it is approriate that the grinder direction doesn’t change between the steps.

The grinding tool must not go over the sheet edges: this is achieved defining the sheet “minimum trim” below which the grinding won’t be performed.