New features of Perfect Cut Release 6.4 Service Pack 2

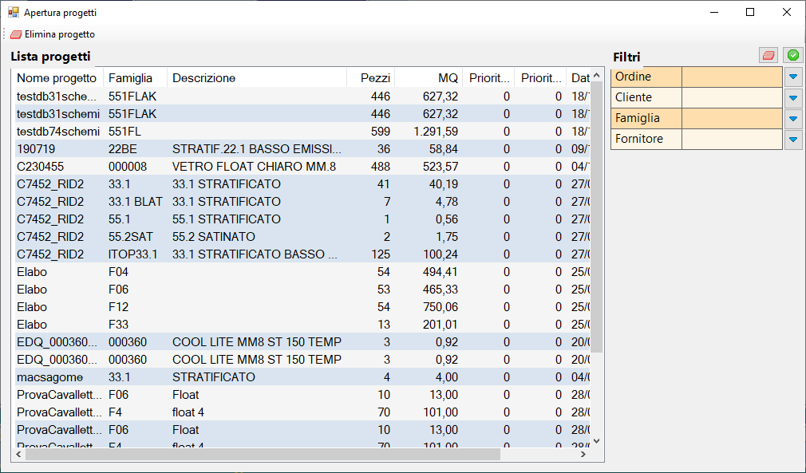

Projects on SQL Database

If Perfect Cut is configured to manage the projects on the database, and if the «Export DB» option is enabled, the function «Open», accessible from the menu or the toolbar, will open the window to select projects from the database, which shows the information about the project (family, number of pieces, number of layouts, date, etc). In any case it’s still possible to open the old interface from the tools menu.

Stock shared with ERP

It is now possible to sync the stock of the families defined in Perfect ERP with the one displayed on Perfect Cut.

The basic parameters of the families and the sheets, like size, borders, trims, can be modified in Perfect ERP and imported dynamically into Perfect Cut.

In the stock window the families which lack the basic parameters will be shown in red.

In the same window it’s now also possible to copy and overwrite the machine parameters from a family to another using the right click menu.

Perfect Label

In the Date field it is now possible to select the format of the date shown (dd/mm/aa, mm/dd/aa or others) and change the separator.

In the Dimensions field it’s possible to force a different unit of measurement from the one in the configuration, allowing to show different fields with different units (inches, millimetres, etc).

It’s possible to use a new sorting method for the labels, which sorts the labels by the cutting layout order, but with the normal order of the pieces inverted (from last to first).

A new parameter that allows, from batch files, to import a file IMP and automatically print the labels and after that automatically quit Perfect Label has been added. The command is /I /P «file_name».IMP.

It’s now also possible to configure a variable bitmap, dependant on the subfield 9 of Note 1, usually imported (through IMP files) from ERPs.

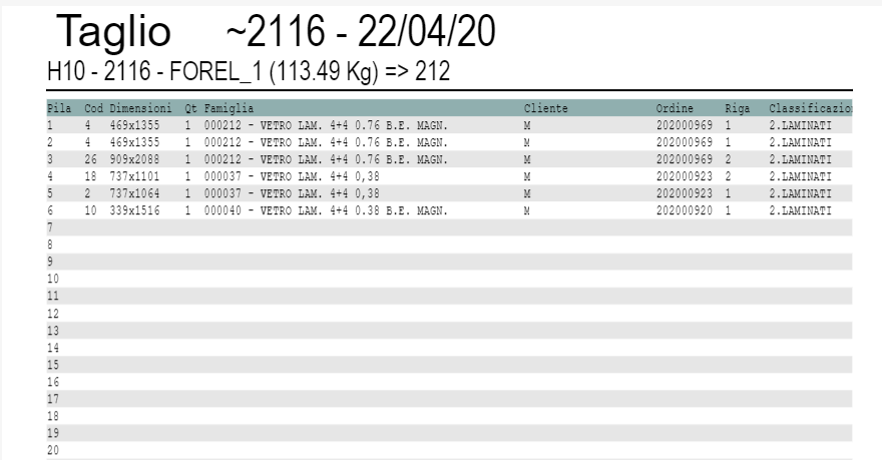

«Machine» type harp racks

A new type of harp racks «machine» has been added, which allows to manage a new separation of pieces using the new «classification» field in the pieces window, with the possibilites of defining the reservation of some slots (not adding them right after the cutting but only before they’re moved to the delivery racks). It’s also possible to manage the excluded pieces and move pieces from one classification to the other.

From the batch project all the pieces of all families are assigned, and then from the cutting project the pieces of external projects are shown in violet and the reserved ones in fuchsia.

The reserved pieces will also be assigned to another rack to show the temporary position of the piece after cutting.

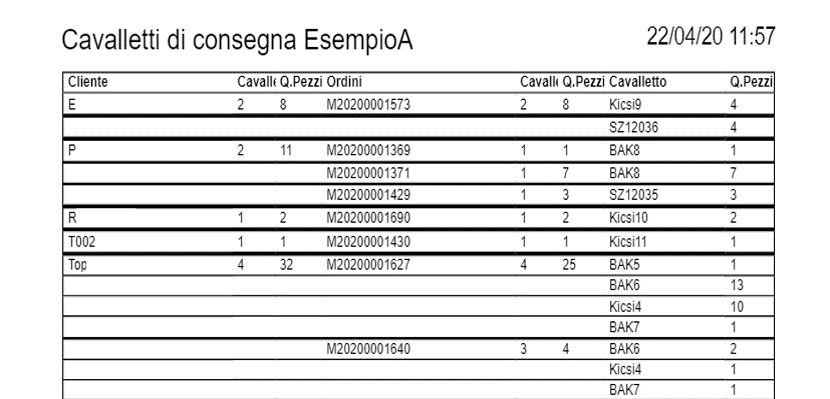

Rack management prints

Two new types of prints have been added to help with the rack management:

1) Summary print for clients/orders for the delivery racks, available from the toolbar in the racks display.

2) Harp racks tabular print, enabled in the rack configuration, to display the information of the pieces in every slot, which replaces the drawing of the harp rack with the informations grouped up.

Import

The import of OPT files has been completed with all the parameters, including the lowE asportation differenciated on the sides of rectangular or shaped pieces.

It’s now possible to import an external file (OPT, OTD) from batch files, adding a line in the file with the «IMPEXT» key, for example “IMPEXT .OPT”.

The DXF import now handles automatic connectors with tools different from the shaped cut, as for example vinyl.

The new field «classification» in the pieces window (for the assignation of pieces to harp racks) has also been added to the standard import (IMP format).

Various changes

Perfect Editor: in the cases which Perfect Cut is configured to interact with automatic stocks Movetro / Mistrello, it’s now possible to send a request to return a tail to the stock directly from the right click menu on the pertained tail.

The management of broken pieces has been improved and now the exported broken pieces will be remembered, to display a warning to the user if a piece has been mistakenly added twice.

A new command for the batch mode allows to copy a file:

COPY <source_file_path> <destination_file_path>

It’s no longer necessary to run an initial external query if the user wants to configure the interaction of Perfect Cut with a database. «Force DB Checker», available in the «Perfect ERP» dialog, in the General configuration, will now create all the initial tables for the DB.

Intermac NC

For the laminated cut machines it’s possible to exclude the shapes from the LowE management.

The LMH models are now supported with a limitation on the cut type, for which it’s not possible to execute pre-scoring.

Multi-passes LowE: management of the overlapping from one pass and the other is now also possible for shapes.

It’s now possible to select the «only true entities» when using a LowE material to allow the use of the roller only on rectangular pieces and on the shape entities, excluding the rectangles that contain shapes without entities on the borders.

In cases of sequential cuts (small pieces cut by difference) and LowE material, if the pieces occupy the entire transversal the roller will now go through the borders of the sheet.

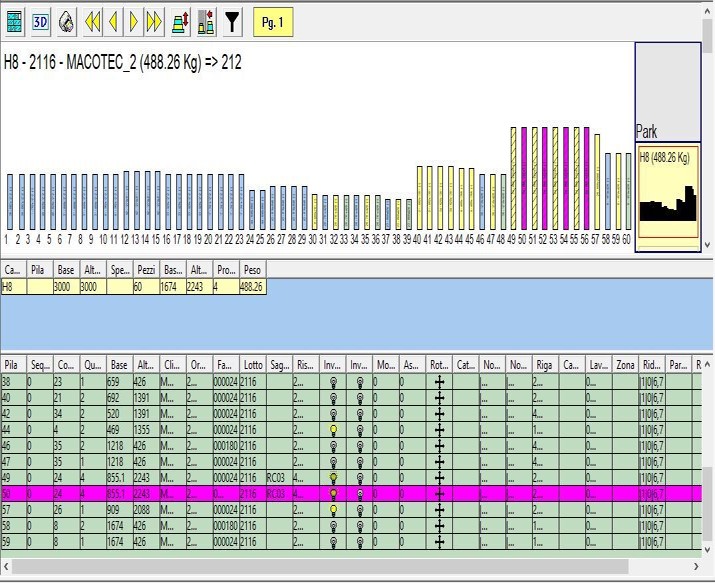

Laminated Macotec NC

A new «nested» cuts management has been added. This allows to score the Z cuts right after the X cut of the transversal and before the Y cuts. Once the Y cuts are executed the pieces will need to be separated manually, which can happen at the same time of following cuts being executed on the machine.

This feature depends by different parameters, like the maximum width and height of the transversal, the maximum number of Z cuts, and the maximum cost allowed (which considers the length of the cuts and the thickness of the material).

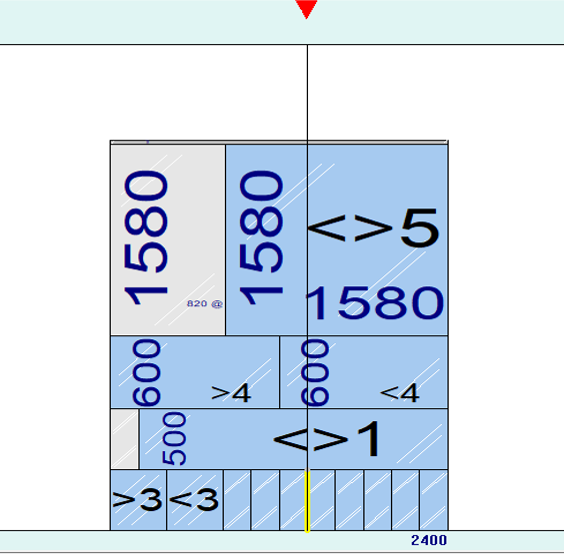

In Perfect TV the nested cuts are displayed in yellow, and the pieces out-feed can now show up to 4 different pieces.

Various numerical controls

Bottero NC: in cases where the Bottero machine is configured for the automatic labeling, it’s now possible to disable the printing of the labels for some pieces by adding «NO_LABEL» in the description of the pertained pieces.

HEGLA NC: in the management of laminated material, if the final tail of a sheet is included in the parameters defined in the configuration (minimum and maximum width of the tail), an additional cut will be added to split the tail in two, to help the user to dispose of the tails which are too small to be reused.

CLIMAX NC: it’s now possible to use the automatic labeling of the Climax machines by adding the management of the LABELS section in the file ISO.