New features of Perfect Cut Release 6.3 Service Pack 5

Stock

It is now possible to merge the active stock with a second one choosen by the user. If there are any duplicate families, a dialog will ask which one of the two (either the current one or the new one) to keep in the stock. This can be useful when installing new machines in clients with Perfect Cut already installed.

New “Create” rack type

A new type of rack “Crate” is now configurable in Perfect Cut which allows the management of the delivery crates. The only normal parameter configurable for this kind of rack is the Depth, but there some other additional parameters for the Tolerance X/Y and the maximum number of types of crates to allow the algorithm to automatically find the best group of crates based on the pieces in the project.

Interactions with automatic stock

It is now possible to use fractional inches in the loader lists for Movetro, according to the parameteres of the maximum fractions set in the hidden configuration.

Perfect Cut is also now compatible with the new version of the loader lists for the Officine Mistrello stock. The quantities on the stock are updated reading the text file stp_magazzino.txt, updated by Mistrello after reading their SQL Server database.

Graphic Editor

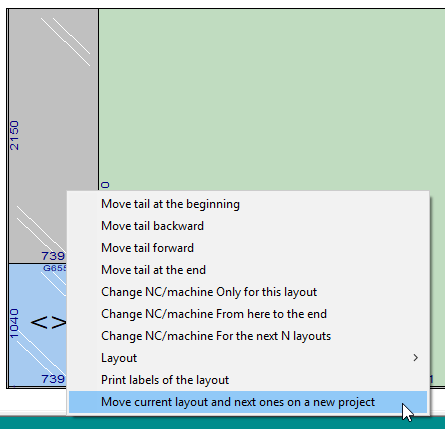

In the layouts it is now possible to use a new function “Move current layout and next ones on a new project” which deletes the layout viewed and the ones after it and copies the pieces removed on a new project.

New features Perfect Label

The “Family” field is now possible to be set to “Weight”, selectable for the whole piece or for the single components, the same way it is possible to do with the thickness. The “Dimensions” fields now keep their format after being merged with another field.

New ellipses with Perfect Shape

Parametric ellipses: a new algorithm of elliptic interpolation has been introduced in replacement to the old one:

- Quality of the the cut improved on ellipses with high base/height ratio.

- Maximum difference of tangents configurable.

- Chordal error extremely reduced.

- Average number of arcs reduced compared to the solution with fixed numbers of arcs.

Layout print

- Color print: if the printer is set to a color mode, the pieces will be colored in the print.

- Shapes print: the closed shapes are colored differently from the external part of the shape in the rectangular piece.

In the case the colored print is not wanted, it is possible to set the “economic print” flag to keep the layouts in black/white.

Spacers management

For the interface with Line Server Lisec the barcode has been added on the TXT field of the TRF file. Moreover the information about the components printed on the label are now managed.In the case of triple staggered glasses, it is now possible to select either the big-small-small or big-big-small mode.

SQL Server interaction

The stock is now readable/writable on a SQL Server database. The quantites are updated in order to mirror the ones on Perfect Cut. Moreover, it is now possible to read the information about the spacers defined on our management software Perfect ERP.

Macotec numerical control

For the laminated numerical control, the shapes with only diagonal cuts passing through are now managed. For all the shapes (or pieces with diagonal cuts) the files .shp are generated which have the information for the diagonal cuts. A parameter in the configuration allows to choose when the shapes have to be cut, when the piece is cut or at the end of the job.

Vetromac numerical control

On the Vetromac numerical control the Low Emission is now managed, in addition to the management of the grinder with the correction according to the offset parameter.